Extend the life of your industrial tires, reduce your carbon footprint, and drive operational savings. At Geelanter, we don't just repair tires—we give them a second life.

In today's world, sustainability isn't just a buzzword; it's a business imperative. The disposal of industrial solid tires contributes significantly to landfill waste and consumes vast resources.

The Geelanter Re-Life Program is our answer to this challenge. Leveraging cutting-edge technology and proprietary processes, we transform worn or damaged polyurethane-filled tires into assets with performance and durability equivalent to new ones. This is the circular economy in action.

Our advantage lies in a meticulous, multi-stage process that guarantees safety, reliability, and performance. The key is our Proprietary Localized Vulcanization Technology, a method that sets a new industry standard.

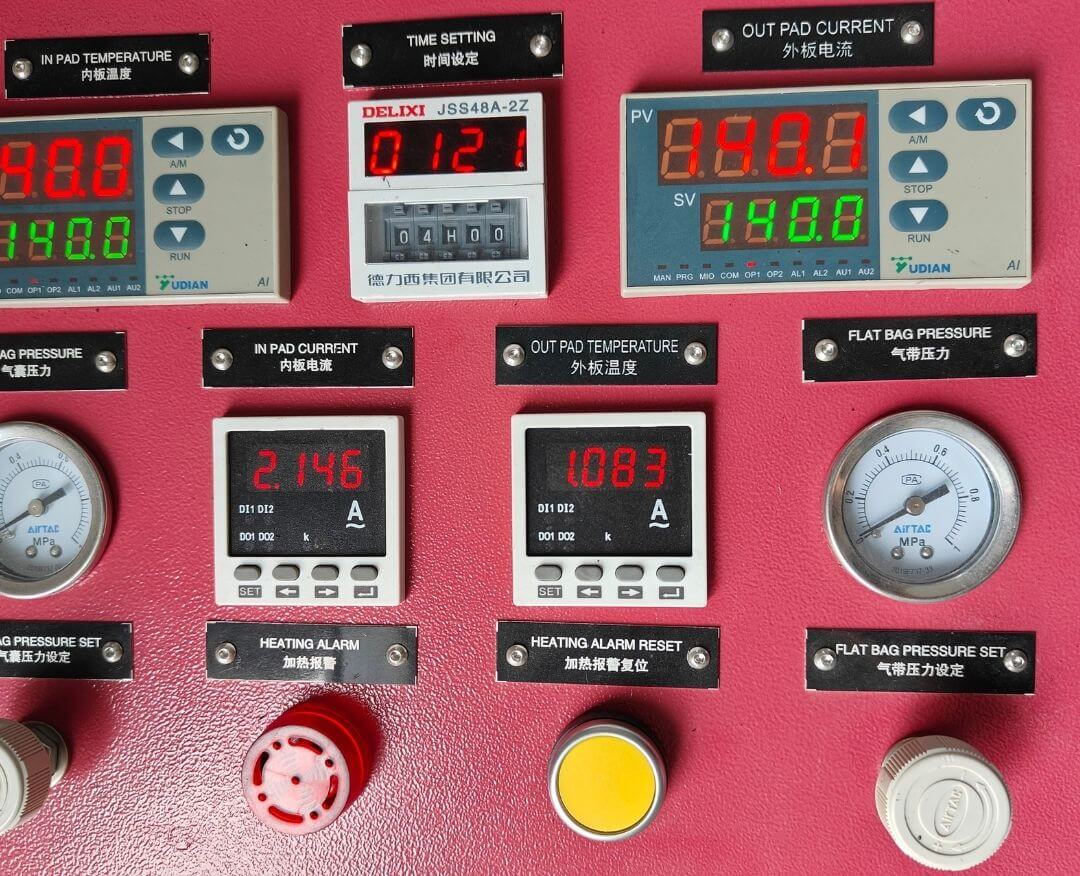

During the vulcanization process, the repair area is heated to approximately 140°C to ensure a perfect, permanent bond between the new material and the original tire body.

To protect the sensitive polyurethane filling from this high temperature, we utilize an advanced heat-blocking technology.

This critical step insulates the tire's core, preserving its structural integrity and ensuring the remanufactured tire performs flawlessly even in the most demanding conditions.

We commit to excellence by using only the world's most advanced, premium-grade repair materials and adhesives. Our entire process adheres to the strictest international operational standards, ensuring every Re-Life tire meets rigorous quality benchmarks.

Every tire undergoes a thorough inspection to ensure its core structure is sound.

Professionally ground and cleaned for perfect adhesion and repair foundation.

Bonding agents and rubber applied with molds to match original tread.

Surface integrity checks and hardness testing to ensure performance.

Choosing the Geelanter Re-Life Program offers tangible benefits:

Significantly decreases the number of tires sent to landfills.

Reduces the demand for new rubber, polyurethane, and steel.

The remanufacturing process is far less energy-intensive than producing a new tire.

Provides a high-quality, reliable alternative to purchasing new tires, lowering your total cost of ownership.